Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- 231.8K All Categories

- 22 >> Start Here <<

- 12 New Members

- 8 FAQs

- 83.3K Gear

- 37.9K Guitar

- 3.2K Acoustics

- 1.3K Bass

- 14.1K Amps

- 16.7K FX

- 157 Digital & Modelling

- 730 Other Instruments

- 7.9K Making & Modding

- 406 Gear Reviews

- 100 Guitar Reviews

- 72 Amp Reviews

- 119 FX Reviews

- 84 Other Reviews

- 734 Made in the UK

- 932 Theory

- 1.8K Technique

- 2K Live

- 3K Studio & Recording

- 2.1K Making Music

- 202 Events

- 15 Guitar Show 2018

- 762 Plug My Stuff

- 100.6K Classifieds

- 39.2K Guitars £

- 2.6K Acoustics £

- 132 LH Guitars £

- 836 Basses £

- 10K Parts £

- 17.6K Amps £

- 32.8K FX £

- 2.6K Studio & Rec £

- 5.8K Misc £

- 443 Personnel

- 52.7K Chat

- 35.3K Off Topic

- 987 Tributes

- 6.3K Music

In this Discussion

Become a Subscriber!

Subscribe to our Patreon, and get image uploads with no ads on the site!

UNPLANNED DOWNTIME: 12th Oct 23:45

Starting out in guitar building - There will be questions!

SteveF

Frets: 505

SteveF

Frets: 505

Hi all,

After building my @BoltGuitarsUK kit, I have got the bug and want to have a go at something with a bit more of the actual woodworking, so as with everything, I have decided to jump in and have a go at making a guitar. I fully expect to screw this up royally and therefore I will be going cheap for the body/neck materials to begin with.

I will have questions and hope that the wonderful people here will help me out with their knowledge so I thought I would keep it tidy and throw things into this thread as a bit of a progress thread and an ongoing Q&A if that's ok?

I appreciate the level of knowledge and experience in here and I'm sure most of the questions I have will have come up for someone before (of course I will try and search for the answers too, but as with anything it seems, the internet is deeply divided even on the basic stuff! (I went down a plane sharpening thread rabbit hole earlier )

)

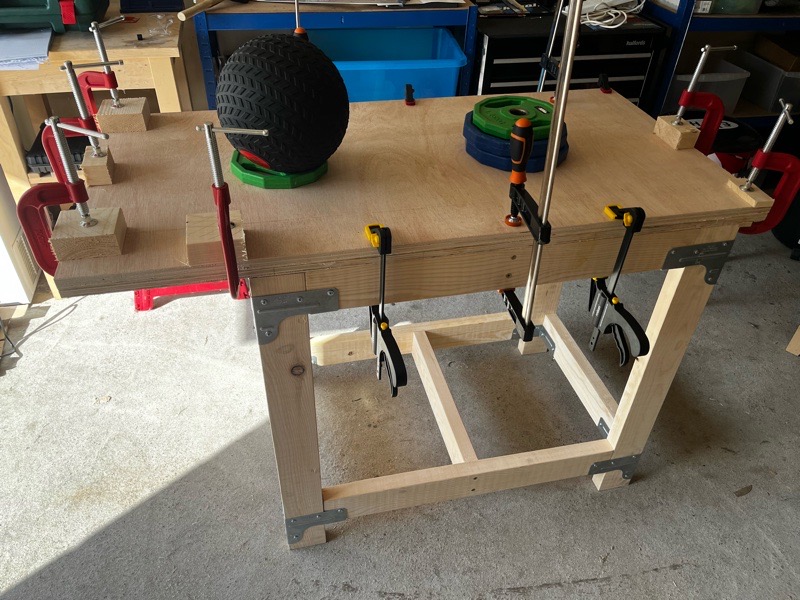

Anyway, the first thing I needed was somewhere to work. The bit of offcut cupboard door clamped to a stool that I used for my kit build wasn't going to cut it for a full build so I built myself a small workbench.

It is still in progress, and still needs a shelf on the bottom and a vice on the overhang. I think I will build an apron on the front which will also serve as the inner face of the vice. I will put some dogholes in the top and on the apron and along with the 2" overhang I left on the back and right hand side, I should have enough options for work holding at least to get me started. The good news is it's solid and doesn't wobble!

The other bit of good news is, by happy coincidence it is almost the same height as this IKEA trolley I have sat in the garage. In fact it is exactly 3mm taller, so I should be able to pop some 3mm hardboard on top of the trolley and that will give me an extension that I can put to the right hand side if I need to support some longer stuff or while cutting anything.

So my first question is, what should I finish/protect the top of the bench with? I was thinking yacht varnish or similar, but wonder whether I should just go for an oil of some kind? Any advice? The top is 2 pieces of 18mm ply. The bottom bit it screwed to the legs and then the top is glued on. Should I screw through the top as well or will the glue (gorilla glue original wood glue) be enough?

After building my @BoltGuitarsUK kit, I have got the bug and want to have a go at something with a bit more of the actual woodworking, so as with everything, I have decided to jump in and have a go at making a guitar. I fully expect to screw this up royally and therefore I will be going cheap for the body/neck materials to begin with.

I will have questions and hope that the wonderful people here will help me out with their knowledge so I thought I would keep it tidy and throw things into this thread as a bit of a progress thread and an ongoing Q&A if that's ok?

I appreciate the level of knowledge and experience in here and I'm sure most of the questions I have will have come up for someone before (of course I will try and search for the answers too, but as with anything it seems, the internet is deeply divided even on the basic stuff! (I went down a plane sharpening thread rabbit hole earlier

Anyway, the first thing I needed was somewhere to work. The bit of offcut cupboard door clamped to a stool that I used for my kit build wasn't going to cut it for a full build so I built myself a small workbench.

It is still in progress, and still needs a shelf on the bottom and a vice on the overhang. I think I will build an apron on the front which will also serve as the inner face of the vice. I will put some dogholes in the top and on the apron and along with the 2" overhang I left on the back and right hand side, I should have enough options for work holding at least to get me started. The good news is it's solid and doesn't wobble!

The other bit of good news is, by happy coincidence it is almost the same height as this IKEA trolley I have sat in the garage. In fact it is exactly 3mm taller, so I should be able to pop some 3mm hardboard on top of the trolley and that will give me an extension that I can put to the right hand side if I need to support some longer stuff or while cutting anything.

So my first question is, what should I finish/protect the top of the bench with? I was thinking yacht varnish or similar, but wonder whether I should just go for an oil of some kind? Any advice? The top is 2 pieces of 18mm ply. The bottom bit it screwed to the legs and then the top is glued on. Should I screw through the top as well or will the glue (gorilla glue original wood glue) be enough?

0 LOL 1

LOL 1 Wow! 1

Wow! 1 Wisdom · Share on Twitter

Wisdom · Share on Twitter

LOL 1

LOL 1 Wow! 1

Wow! 1 Wisdom · Share on Twitter

Wisdom · Share on TwitterBase theme by DesignModo & ported to Powered by Vanilla by Chris Ireland, modified by the "theFB" team.

Comments

Further power tool question - I don't have a bandsaw yet (and it may be a while) and I am planning to cut out the body with a jigsaw. Do I need any particular kind of blades that people would recommend? I think the body will be something like poplar, neck maple or similar and fingerboard - whatever is cheap! Will a jigsaw go through all that at the depth of a body/neck blank? Anything to watch out for?

Thanks all in advance - your help is always much appreciated!

I’ve built a fair few guitars now, and my bench top(s) is(are) still fine.

A sheet of thin (cheap) sacrificial MDF?

Router bits.

Mostly, people build using templates. You get / make the templates, and then copy the shape of the template onto the blank using bearing guided router bits. Sometimes the bearing is above the cutter, sometimes below it.

Wealden Tools is a good source. You’ll probably need 3-4 bits of varying length.

Are you following a plan / approach for this build, or making it up as you go along? Building a guitar is complex, but simple if you break it down into the 100-odd simple jobs that come together to make the guitar. The trick is doing those 100-odd jobs in the right order.

Thanks, I will check out Wealden. I assume I need something good quality and sharp to avoid damaging/gouging the body. In terms of radius of the bits, what is the biggest/smallest I will need for straight and what roundover?

I watched a Crimson 5 video series on Triton tools channel of building a Tele style and whilst there were little bits skipped over a bit quick, I think the general flow seemed to make sense. It was this one

PS

If you really get into this building thing, Mark Bailey runs courses just down the road in Ayr.

As with all tools they can be expensive. I’d buy what you need when you need it. If your working area is damp then keep the edged tools in the house.

it has a 1/4” and 8mm collet apparently

I’ve got a big 1/2” jobbie too, but it’s not necessary for guitar building. Manoueverability is more important. Make yourself a decent router base - that’ll make some of the jobs a lot easier.

Mark is a brilliant teacher. Website is crap. Best to phone them (and it might take many attempts to get through!) or email.

Are there better bits? Sure, but that set was fine for me. From what I remember it was the cost of roundover bits that made me look at it.

Got some templates and timber on order. I'll update when I have them.

Adam

The other thing i would absolutely recommend are books by Melvyn Hiscock, and Cumpiano/Natelson. The Cumpiano is acoustic based, but the info is absolutely applicable to electrics and the writing style is a rare treat.

I went pretty cheap for this first build - I fully accept that I may duff up a blank or two so I went with poplar/tulipwood for the body and a plain maple neck with rosewood board (I do have a pre-slotted board too in case my initial attempt fails, but figured I would have a go) I'm not worried about the grain etc on the body blank - it's going to be painted.

I also picked these up on eBay. They seemed to be the most comprehensive templates I could see on there, marked with centrelines etc. Hopefully they should work ok. My first task will be making some copies of the templates. That should help me get comfortable with the saw and router etc.

My first observation is that the slot on the template for the truss rod seems to be approximately 350mm long. Most of the rods I can see for electric online are around 440/460mm. I haven't bought one yet as I wasn't sure which I needed. Am I to assume that the slot in the template provides the end of the slot and you would extend it one way or another depending whether you want the adjustment at head or heel and. based on what length your particular rod is?

Curious that the truss rod slot is so short. It has to extend to either the headstock or the heel. Try asking the seller?

I did assume that was the case with the truss rod. I can only assume it's to give the option to do either. I think I will be planning on doing a headstock adjustment. I will send the seller a message and see what they say